1. INTRODUCTION

Eastwood Energy Joint Stock Company established and built the first wood pellet factory in December 2013 in Chon Thanh 1 Industrial Park, Thanh Tam Commune, Binh Phuoc Province.

– By the end of 2020, the Company inaugurated the construction of the second factory in Xuan Loc commune, Xuan Hoa district, Dong Nai province.

– The company has nearly 9 years of experience in the production and sale of wood pellets. Total export volume is over 400,000 tons per year.

– Main markets: Japan, Korea

– Factory’s locations:

Factory 1:

Lot A5.1-A5.2, Chon Thanh 1 Industrial Park, Thanh Tam Commune, Chon Thanh District, Binh Phuoc Province, Vietnam.

Factory 2:

Soc Ba Buong Road, Group 11, Hamlet 2, Xuan Hoa Commune, Xuan Loc District, Dong Nai Province, Vietnam.

II. PRODUCTION CAPACITY

Factory 1: Eastwood Energy Chon Thanh

– Total area of factory and warehouses: 4.6 hectares

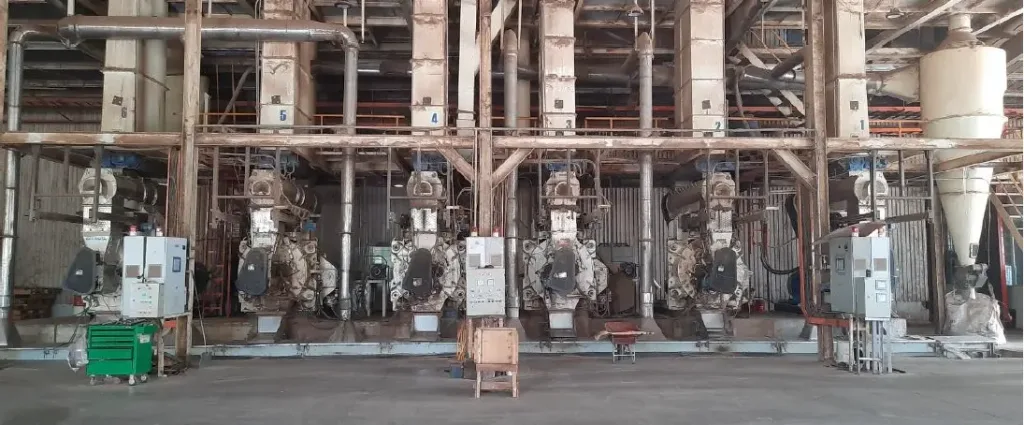

– Production line includes: 2 Vietnamese chippers, 4 Vietnamese wet hammer mills, 3 dryers (1 European belt dryer, 2 Vietnamese drum dryers), 2 European hammer mills, 6 European pellet mills, 1 European pellet cooler.

– Production capacity: 12.000 tons of wood pellets per month.

Factory 2: Eastwood Energy Dong Nai

– Total area of factory and warehouses: 12 hectares.

– Production line includes: 1 woodchipper, 2 wet hammer mills, 3 dryers (Vietnam dryer), 2 dry hammer mills, 3 pelleting presses. All main machines are made in Europe.

– Production capacity: 16.000 tons of pellets per month.

III. CUSTOMERS

– During 9 years of operation in the biomass industry, Eastwood Energy has supplied to nearly 10 foreign customers.

– Its products have been exported to markets such as Korea, Japan, Taiwan, and Philippines.

– The company has long-term contracts with Japanese customers.

IV. SUSTAINABLE MATERIAL RESOURCES

– The source of raw materials to produce wood pellets at Eastwood Energy is mainly Acacia and Eucalyptus being grown at well-managed plantations.

– Advantages of Acacia and Eucalyptus: Short exploitation life of 3-5 years, reliability, and sustainability. Theirs characteristics ensure the production of wood pellets to meet the I2 standards required by most Japanese end-users such as calorific value, ash, and chemical components.

Read more: Eastwood Energy Profile 2023